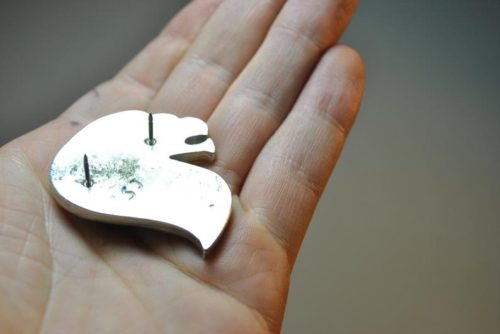

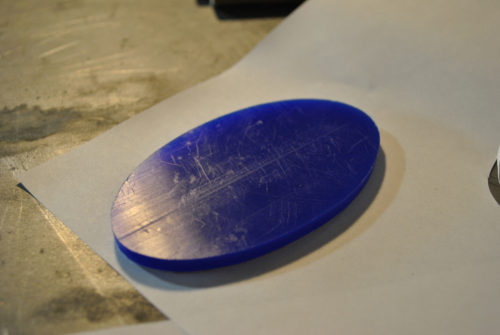

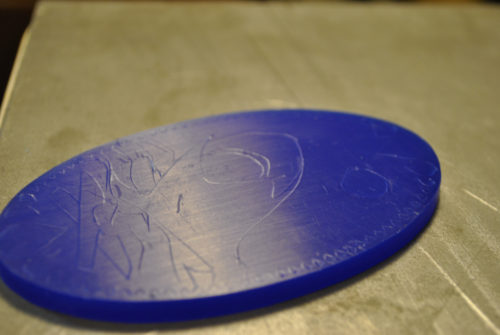

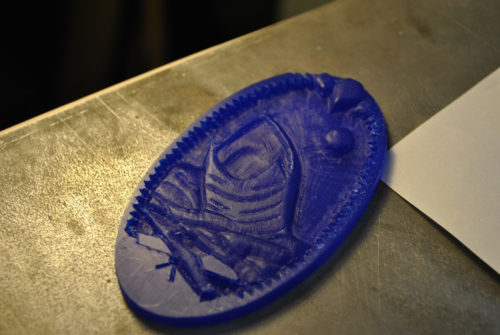

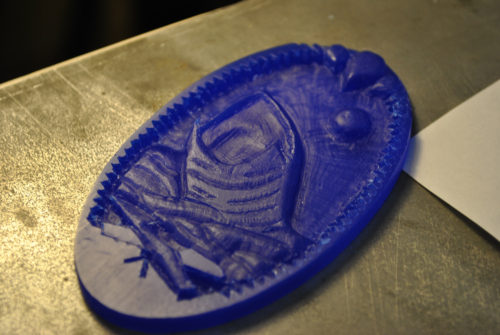

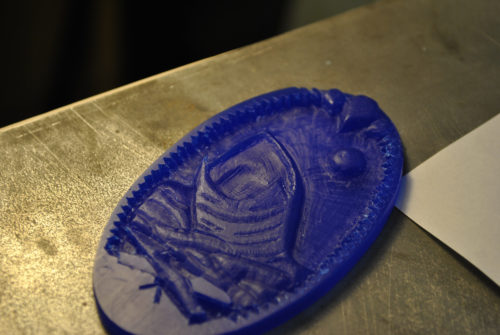

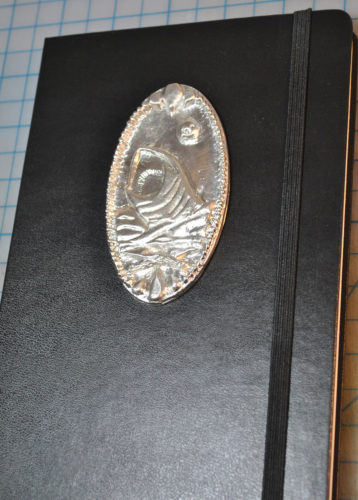

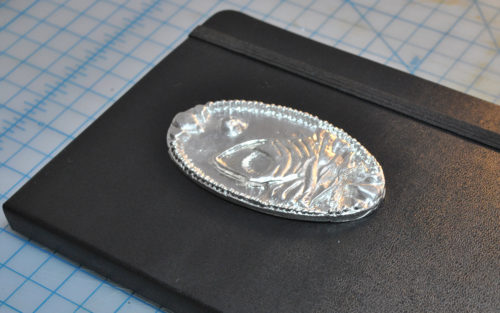

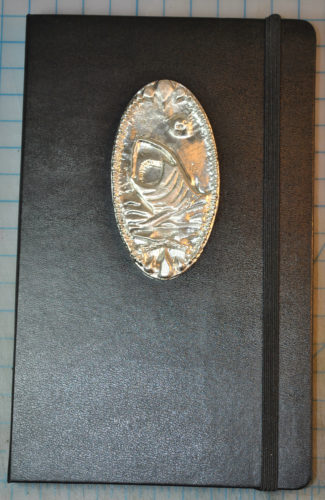

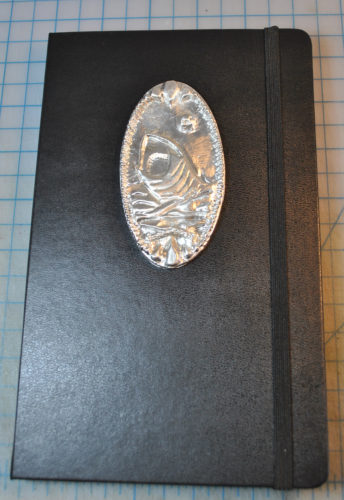

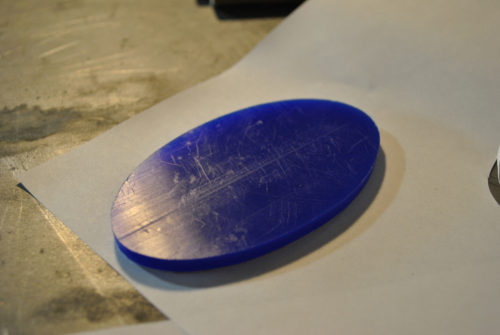

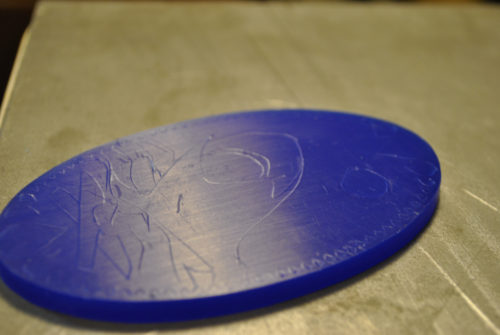

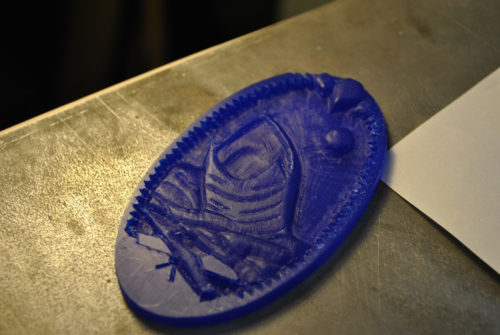

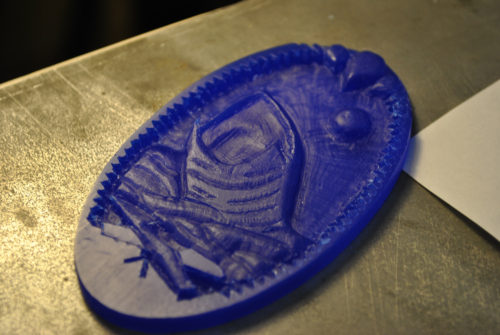

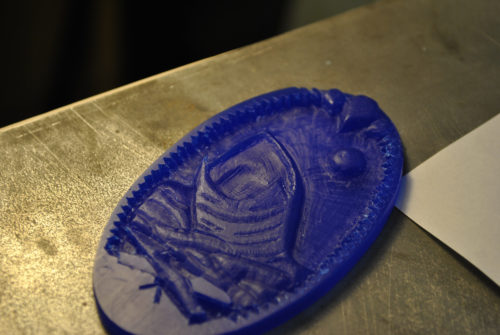

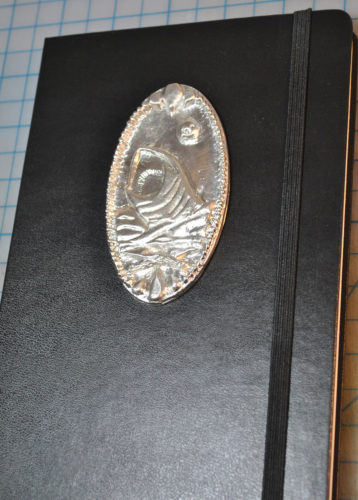

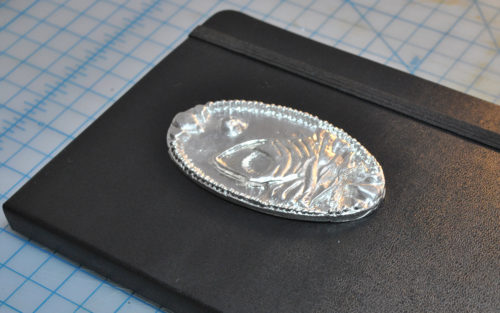

Shai-Hulud and The Atreides Hawk, mix and match these pins to show your love of the Dune books. These are not “hand made” in the sense that they are designed and then made in a factory in china, these are hand carved, hand cast, and hand constructed, as such each one comes out slightly differently.

Hand made to order.

.5 inches wide .5 inches tall for each pin.

Pin back hardware is made from brass, and pin is nickle, design is lead free pewter. Custom built to work on most fabric, but works better on heavy canvas jackets or backpacks. Want to buy a pair, see here, or here.