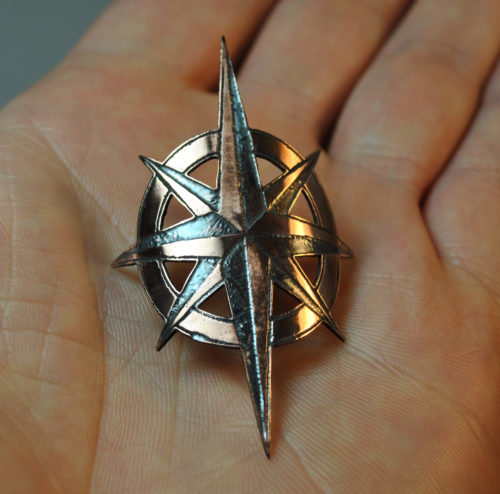

Compass rose head badge for your bicycle, 40mm wide, 55mm tall. Etched copper, and lovely! If you like it you can get one here!

Compass Rose Head Badge

Compass rose head badge for your bicycle, 40mm wide, 55mm tall. Etched copper, and lovely! If you like it you can get one here!